WAREHOUSING AND WAREHOUSE MANAGEMENT SYSTEMS:

FOOD PRODUCTION MACHINERY:

FOOD PROCESS AUXILIARY EQUIPMENT:

LOGISTIC OPERATION MACHINERY AND EQUIPMENT:

|

YOGURT MILK FILLING MACHINE (Click here for the product catalog) |

|

|

No other filling machines manufactured for this purpose are capable of ensuring the hygienic conditions and food safety. By virtue

of this feature, Dimak-Diren Machinery R&D Yogurt Milk Filling Machine holds an entirely different position than the machinery

existing for this purpose.

|

|

ADVANTAGES:

- The machine is specifically designed for performing manual filling operations for yogurt milk and other liquids to the

containers with accurate weight in grams.

- DIMAK Diren Machinery R&D Yogurt Milk Filling Machine meeting all hygienic criteria with its stainless body and equipment

completely suitable for foodstuff demonstrates high performance as guaranteed by the touch screen control panel, and

computer controlled (PLC) command system.

- By virtue of its magnetic flow meter, the machine enables you to eliminate filling waste with its accurate accuracy for weight in grams.

- The machine enables its user to perform filling operations by being connected to the line without requiring extra pumps and ballast tank.

- The machine enables you to experience the comfort of easy and real cleaning by virtue of the CIP-Cleaning in Place system.

- The machine enables you to experience the difference of easy use by virtue of its user-friendly touch screen control panel.

- The predefined special menus enable easy change of weight in grams and perform calibration whenever necessary.

- The machine enables secure and accurate filling operations by virtue of the fully balanced special design which doesn’t

create any difference in weight in grams between the shelves.

- The machine is equipped with command system operating wireless with radio frequency (RFID) technique.

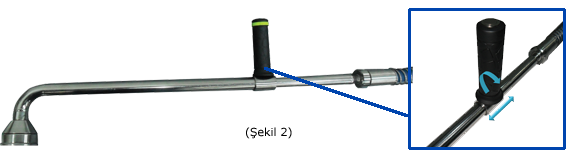

- The machine doesn’t cause fatigue at the machine operators and is operator-friendly by means of the light weighted and

ergonomic filling guns with no cut-off valve, air hose and electrical connection.

- The machine is user friendly with its special filling nozzle not allowing froth and drip.

- The safety system which prevents the operator to perform filling operation under nonconforming conditions greatly

facilitates the operation by automatically terminating the filling operation when any product other than the desired product

temperature is received.

- The machine is able to generate reports for the total number of filling operations and the total weight in grams after production.

- The machine has an elegant appearance; it can be used as mobile unit and it is possible to immobilize the machine at any

desired location by virtue of its braked wheels.

|

|

|

TECHNICAL FEATURES:

| Capacity |

: |

4000 kg/hour (use of 4 guns and 1 Kg container) |

| |

|

6000 kg/hour (use of 4 guns and 5 Kg container)

|

| Power |

: |

220 Volt |

| Air Pressure |

: |

4-6 bar |

| Tolerance |

: |

+/- 3g |

| Dimensions |

: |

Width: 60 cm; Length: 80 cm; Height: 190 cm |

| Material |

: |

Completely manufactured from stainless material conforming to the foodstuff. |

| Miscellaneous features |

: |

Standard production is for 4 or 2 users; and each user is capable of performing simultaneous accurate

filling operations with different weights in grams. |

|

Video: |

|

| Click here for alternative video file format>> |

|